A Comprehensive Guide to Comprehending Litho Printing Methods

The world of litho printing, a method stemming from the late 18th century, is a remarkable blend of background, innovation, science and art. This thorough overview will decipher the complexities of this printing approach, from the structure of litho inks to the difficulties dealt with in contemporary applications. As we venture into the ins and outs of lithography, the significance of automation and sustainability in guaranteeing its future importance comes to be progressively clear. Stick with us as we trip into the fascinating world of litho printing.

The Historical Development of Litho Printing

The historic trajectory of litho printing, a pivotal innovation in the world of interaction, is a fascinating story of human resourcefulness. Birthed in the late 18th century by Alois Senefelder, this technique was initially a cost-effective technique of publishing staged works. Lithography, stemmed from the Greek words for 'rock' and 'to write', used a smooth rock surface to transfer pictures onto paper. The procedure evolved with the introduction of the rotary press, which considerably enhanced performance (litho printing). In the 20th century, the development of balanced out lithography transformed the industry, permitting automation of premium prints. Each phase of litho printing's development showcases humankind's relentless search of performance and high quality in aesthetic interaction.

Decoding the Science Behind Litho Printing Inks

Moving on in the exploration of litho printing strategies, the emphasis now moves to the science behind litho printing inks. The make-up of these inks, their drying out process, and shade mixing strategies form the foundation of this intricate art kind. Recognizing these components is essential to understanding the craft and achieving the wanted print results.

Structure of Litho Inks

In lithographic printing, the essential duty of litho inks can not be overemphasized. Pigments, the color-providing elements, are finely ground fragments suspended in the car, a liquid that lugs the pigment onto the printing surface area. Each component plays an essential component in the final print's top quality, making the precise solution of litho inks an elaborate science.

Ink Drying Process

From the structure of litho inks, interest turns to the fascinating process of ink drying out. 2 key techniques are utilized in litho printing: oxidative drying and absorption. Absorption, on the other hand, includes the ink permeating right into the paper fibers, which is a quicker process yet can lead to less dynamic colors.

Color Combining Techniques

While the drying procedure plays a crucial function in litho printing, the science of shade blending strategies holds equivalent relevance. The science behind litho printing inks likewise takes right into account the openness of the ink, which influences exactly how shades overlay and mix.

The Art and Style Elements in Litho Printing

Litho printing takes a breath life right into art and design with its unique aspects. The procedure involves developing an image on a lithographic sedimentary rock plate or steel plate with a smooth surface. The picture is after that printed onto a medium, normally paper, by transferring the ink from the plate. What sets litho publishing apart is its capacity to replicate intricate styles with high integrity, making the output practically identical to the original artwork. This is attained through the usage of different line strategies such as cross-hatching, hatching, and stippling, which enable a variety of tonal effects. Litho printing fits a selection of colors, allowing artists to create vibrant and vivid prints. This check over here combination of precision and adaptability makes litho printing a recommended option for numerous musicians and designers.

Modern Applications of Litho Printing Strategies

Litho printing techniques have actually located considerable use in the modern-day commercial market. Its impact and value continue to expand with the arrival of new developments and technologies in the field. This area will certainly check out these contemporary applications and the transformative role they play in the printing sector.

Business Litho Printing Makes Use Of

Litho printing stays a critical part of the commercial industry. High-volume printing tasks, such as the manufacturing of books, newspapers, and product packaging, depend on litho printing for its capability to supply exceptional picture quality and price efficiency. Litho printing also supplies a wide color range, premium to that of electronic printing.

Technologies in Litho Printing

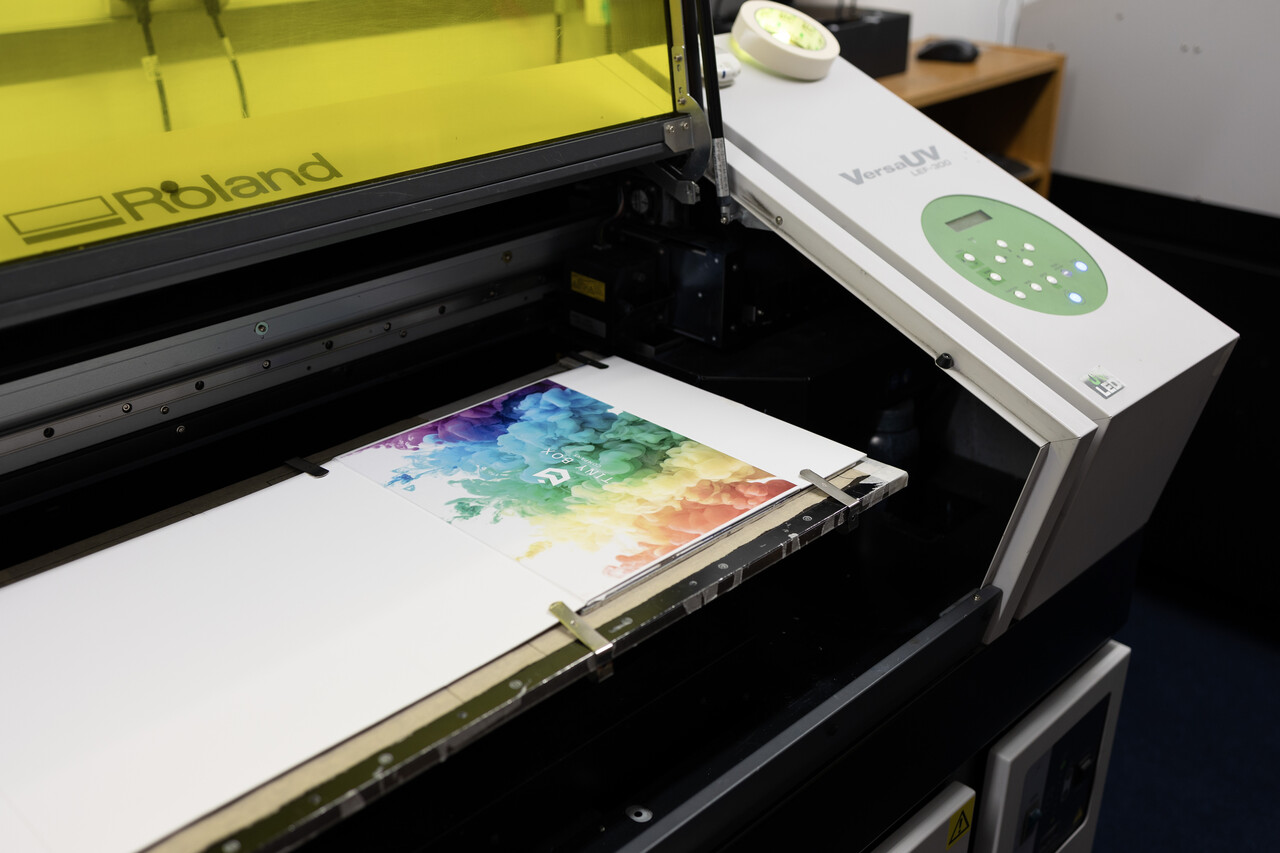

Pushing the limits of typical techniques, modern-day innovations have actually sustained a host of technologies in litho printing. One famous advancement is digital litho printing, which incorporates the virtues of digital innovation with litho's premium output. These technologies emphasize the long-lasting importance of litho printing in the modern globe.

Exploring the Process of Litho Printing: Detailed

Obstacles and Solutions in Contemporary Litho Printing

Despite the precision and practice that litho printing happily promotes, it is not without its collection of modern obstacles. Digital litho printing permits for cost-effective brief runs and easy personalization, dealing with the problem of variable data. Thus, while there are challenges, the litho printing sector is proactively adjusting to meet them head-on, review guaranteeing its importance in the future.

Verdict

In verdict, litho printing, with its rich background and scientific intricacies, holds a considerable place in the print sector. The future of litho printing pivots on its capability to adapt to these transforming needs, verifying its enduring worth in a progressing market.